PRODUCT INSIGHTS

July 28, 2021

The heart of every fountain pen that can make or break the ease of writing is the pen nib. Let's take a look at the production process, where each nib is made carefully by hand!

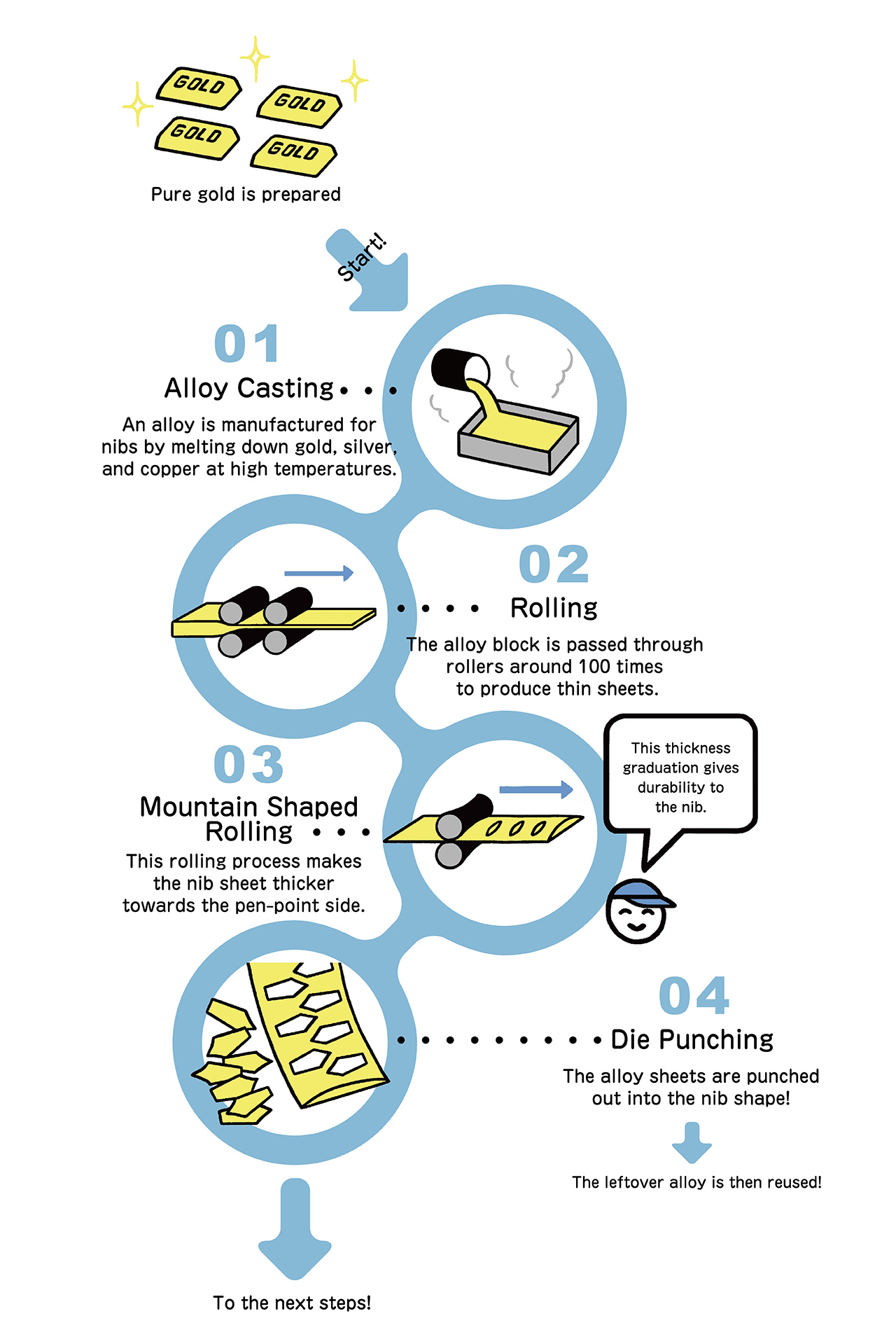

It has been over a century since PILOT began manufacturing and selling fountain pens. And only PILOT manufactures everything from the pen points of fountain pen nibs to the final product, even when looking worldwide! Let’s take a look at the process of manufacturing nibs for fountain pens.

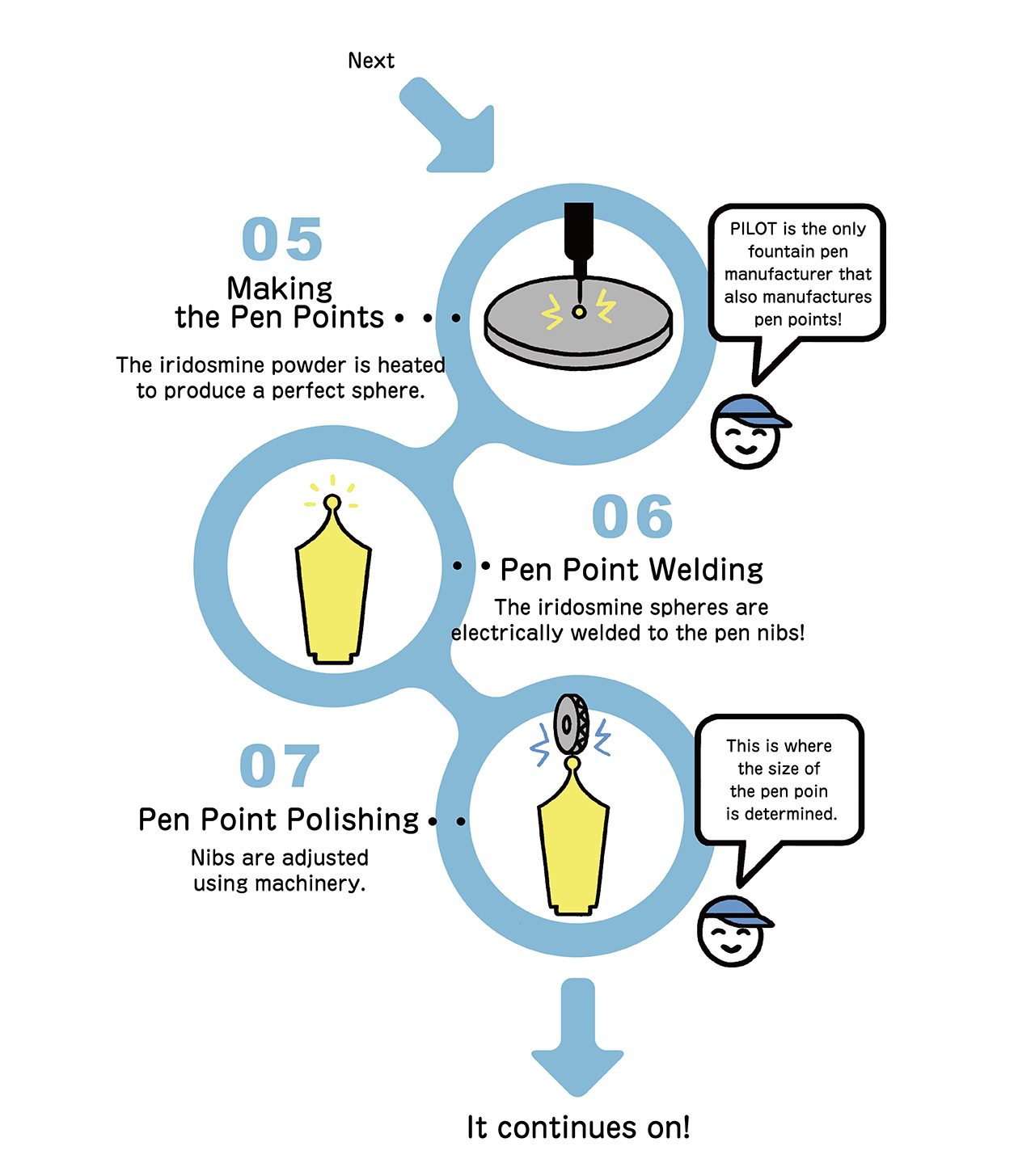

PILOT manufactures not only the nibs themselves but also the small spherical pen points at the tip of the nibs.

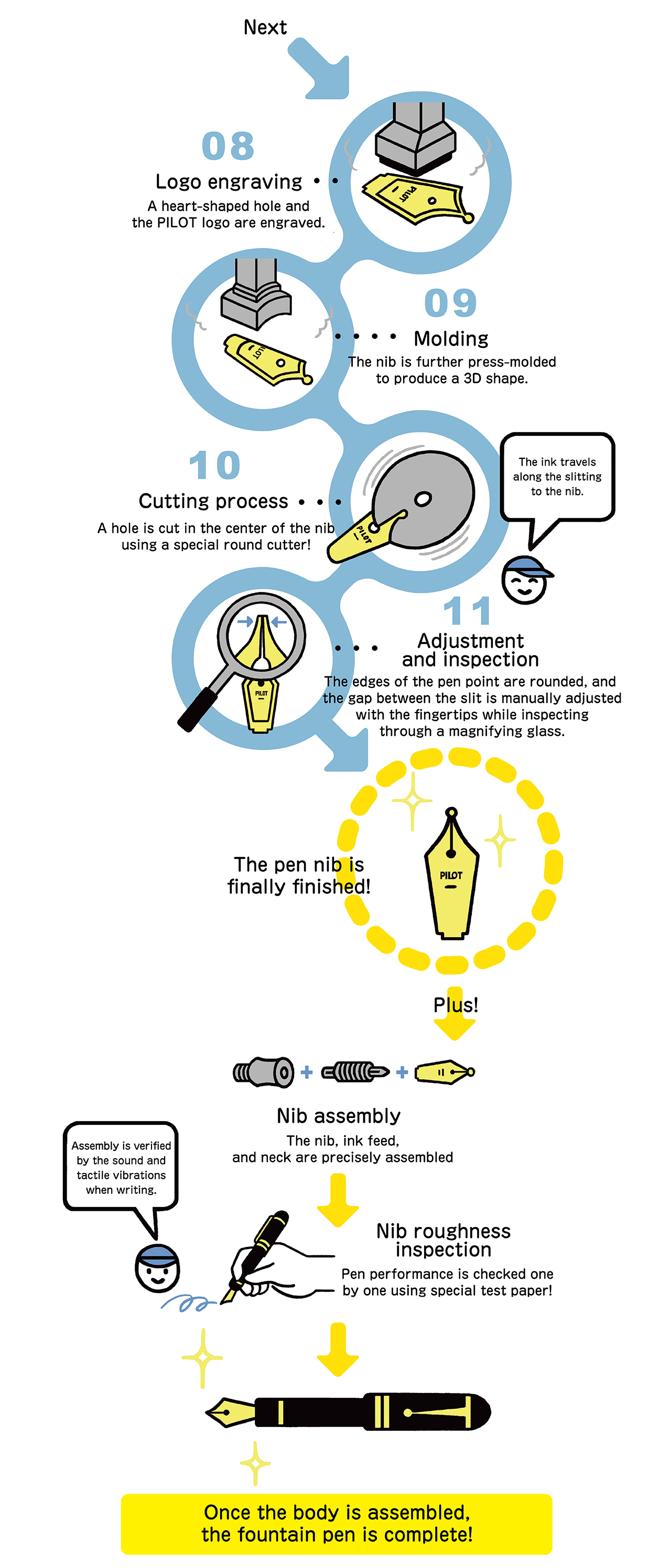

The pen points are made of iridosmine powder (iridium and other platinum group metals). Through the process of producing this material, forming the spherical shape, and selecting each pen point, the iridosmine spheres are welded to the nibs instantly using electricity. After polishing and adjusting each pen point, we finally head into the final stage of production.

Having been engraved and molded, the nibs move on to the slitting stage to manufacture a channel for ink flow. Each nib is carefully checked as it continues through the finishing process. Almost finished!

There are so many steps involved in crafting a fountain pen nib! Learning how they’re made might help you feel more connected to fountain pens. Why not give one a try yourself?

<

1

2

>